Precision in the Sky: Enhancing Image Rotation Accuracy through Three Axis Stabilization

Three-Axis Stabilization: The Backbone of Pin-Sharp Aerial Photography

Capturing perfectly sharp aerial images is impossible without a rock-solid platform. Three-axis stabilization technology ensures that stability by continuously correcting pitch, roll, and yaw—so every frame remains locked to its intended line of sight. Whether you’re shooting cinematic footage or conducting precision inspections, this technology is the quiet hero behind the scenes.

1. How Three-Axis Stabilization Works

1.1 Sensor Fusion for Real-Time Awareness

Modern gimbals rely on a blend of micro-gyroscopes, accelerometers, and magnetometers, rather than a single sensor stream. These measurements are fused by a flight-control computer, producing a high-resolution motion profile. By comparing predicted and actual positions thousands of times per second, three-axis stabilization systems know exactly when—and how much—to correct.

1.2 Lightning-Fast Servo Corrections

When an error occurs, brushless servos respond within milliseconds, nudging the camera back on course. This immediate reaction keeps the horizon level and framing intact, even in turbulent air.

1.3 Built for Tough Sky Conditions

Air turbulence, sudden gusts, or sharp turns introduce vibration and shock. Aerospace-grade aluminum alloys, multi-stage dampers, and vibration-isolated circuit boards prevent these forces from degrading stability—ensuring that three-axis stabilization works reliably for years.

2. Flight-Path Compensation in Practice

When a drone deviates from its planned course—such as during a rapid yaw turn—the stabilization controller interprets the change and applies counter-motion. The footage remains smooth and aligned with the intended flight path.

Each metric passes through a Kalman filter, removing noise and producing precise servo commands. This is the computational backbone of three-axis stabilization accuracy.

4. Quantifying the Subjective

Qualitative issues, like “camera feels jittery,” are turned into measurable indicators—such as ±0.02 g vibration thresholds or jerk limits in m/s³. Once quantified, the system automatically suppresses them, further improving three-axis stabilization performance.

5. Rugged Circuit and Structural Design

Aerospace-grade PCBs feature reinforced solder joints, conformal coatings for humidity resistance, and heat-dissipating enclosures. This prevents thermal drift from affecting sensors—critical for maintaining three-axis stabilization precision in changing climates.

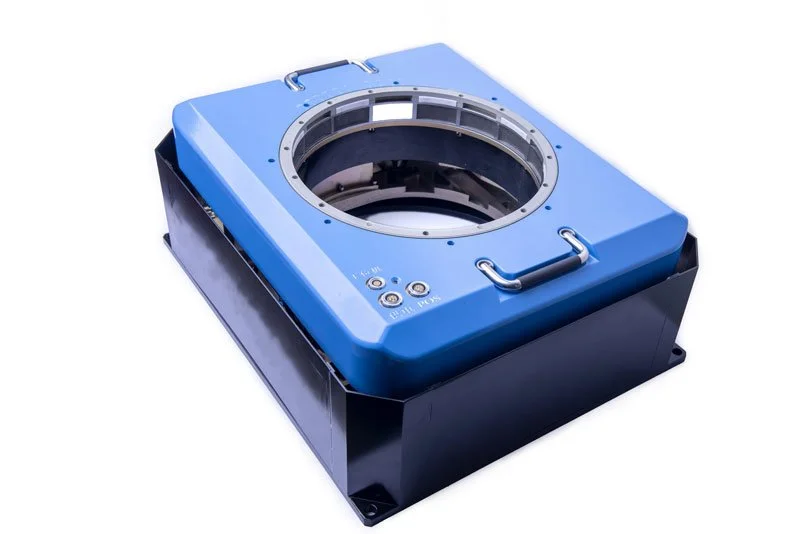

6. Custom Solutions from Changchun Huanxin Co., Ltd.

From ultralight quadcopters to manned platforms, Huanxin engineers customize torque, sensor precision, and mounting to ensure optimal three-axis stabilization for every application.

7. Expanding the Possibilities of Aerial Imaging

Sharper, more stable images enable:

High-resolution mapping

Cinematic filmmaking

Infrastructure inspection where blur could mask defects

8. What’s Next?

The future of three-axis stabilization includes AI-driven control loops that predict turbulence, lighter composite frames that save weight without losing rigidity, and onboard image processors that cut latency even further.

9. Key Takeaways

Need a Tailor-Made Stabilization System?

Visit our solutions page to see how Huanxin Co., Ltd. can align three-axis stabilization technology with your mission profile.